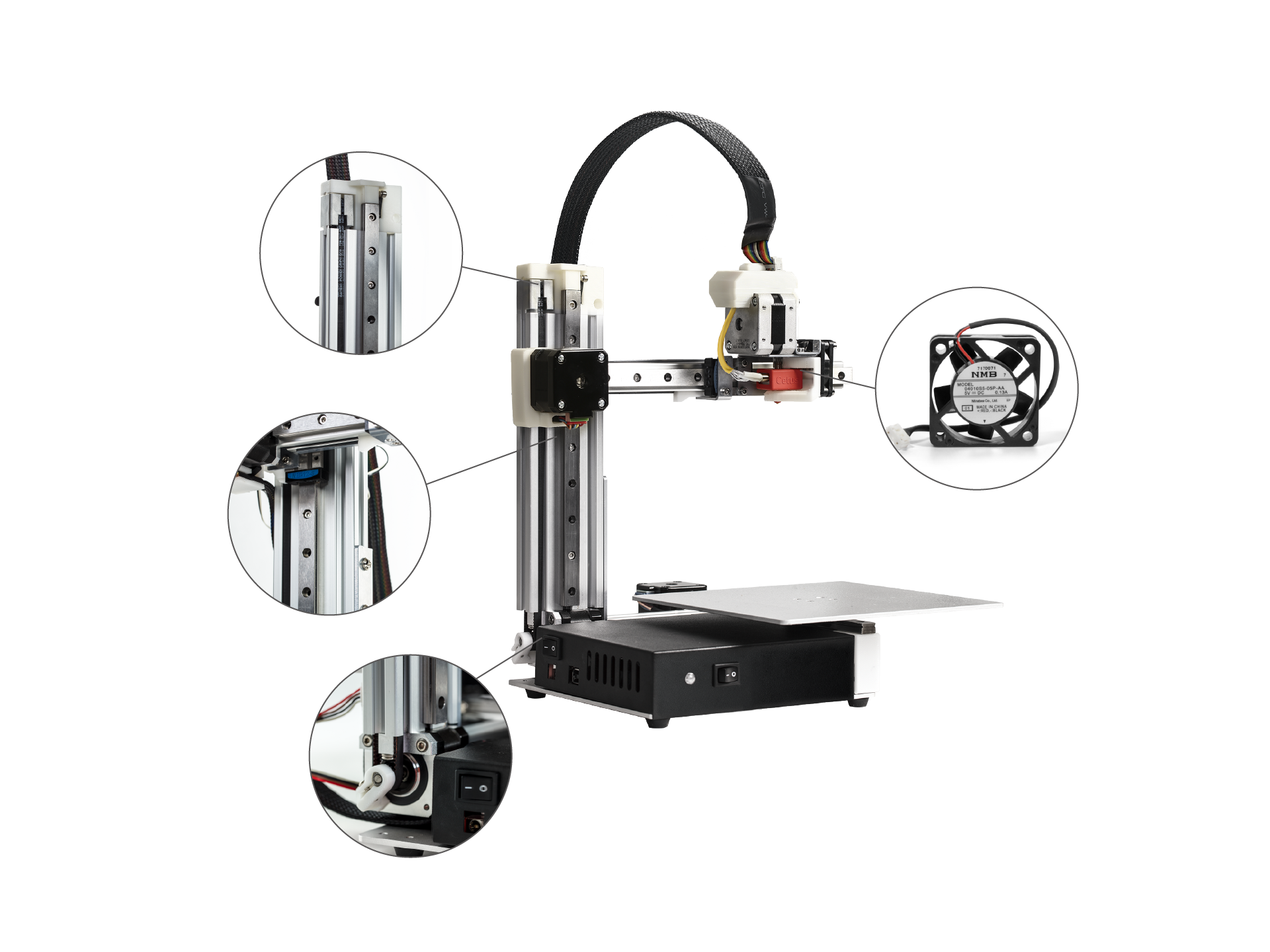

Filament diameters of around 0.38 translate to the 2200% cmeyer posted (flow rate factors in quadratic, so use fine steps when adjusting it). Flow rate percentage adjustments mess up the ‘layer view’ in Cura (from years of experience with an Ultimaker 2, I find this one of the most helpful features in Cura). I don’t know about Delta but United has a link to them in their app. Spec 4. Monitor and control multiple printers in one place. Support connection to multiple printers through Wifi. Keep in mind that you may have to find a physical solution for levelling the build bed when using Cura.ĭ) With the current version of Cura (v3.3.1) it is better to adjust the flow rate of molten filament via the filament diameter, than the flow rate percentage. ARM-based microcomputer, with Wand server pre-installed. The nozzle is too far away from the bed, if the individual lines can be easily separated and do not stick together.)Ĭ) Up Studio allows for an 9-point calibration routine for the z-axis. Cetus 3D Printer MK2 Cetus MK2’s final inventory in Japan Stock / Russia Stock USD 249.00 USD 349. The nozzle is too close to the bed, if the brim thickness (z-direction) gets to thin and translucent. If you use a brim around a test-model in Cura, the correct height is achieved, if the individual lines that make up the brim squash together nicely. (I think a painfully precise calibration is overkill.

#Cetus3d delta code

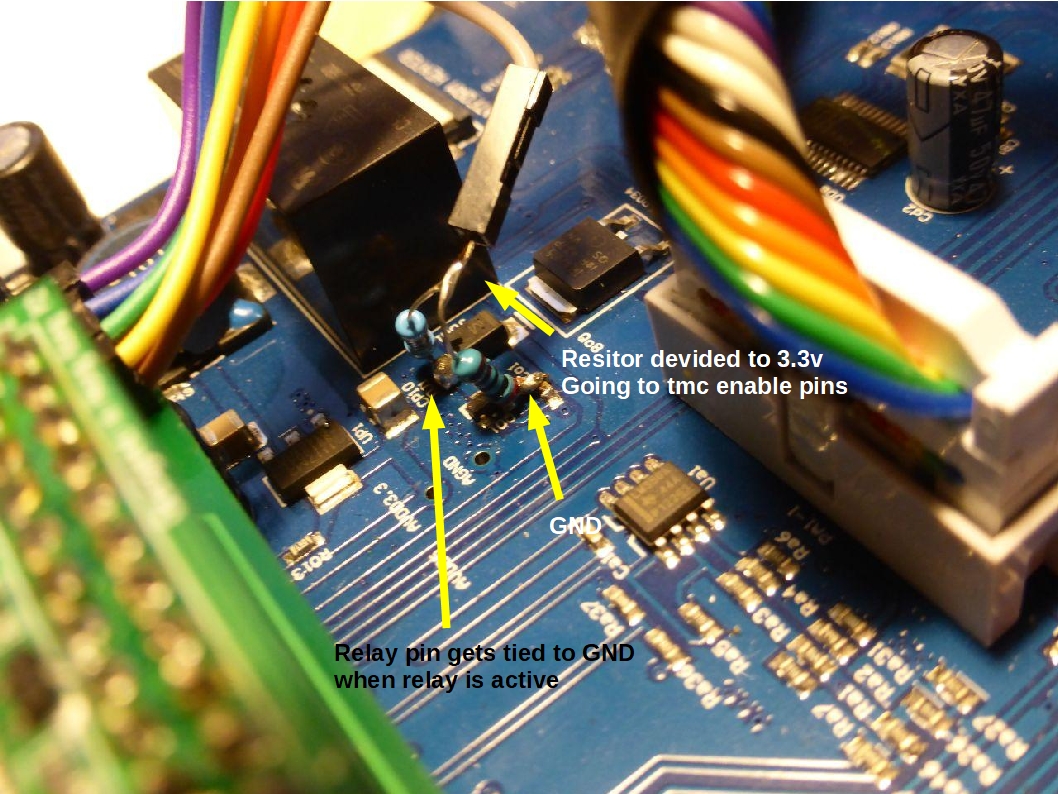

I did compile my ‘own version’ from the start code by chrisevich. Perhaps the info below will help someone in the future:Ī) I used the start and end code from chrisevich ( #11) which worked nicely for me.ī) the z-axis calibration code posted by cmeyer never worked for me. I just wanted to thank everyone who contributed to this thread - it helped me tremendously when setting up my Cetus3D MkII with Cura. Home 3D Printers Cetus2 3D Printer Deluxe Version with 2KG PLA 599. G1 X50 E360 F300 extrude a 5cm purge line Cetus3D Dual Extrusion Multi-color Multi-material 3D printing. G1 X2 Y178 F5000 move to back right corner

M206 X-180 offset X axis so the coordinates are 0.180, normally they are -180.0 Do the paper test and use a gcode file something like this:p.p1 the nozzle offset may be different than in Cetus Studio. make sure your nozzle offset is correct in the starting g-code

0 kommentar(er)

0 kommentar(er)